Across industries like pharmaceuticals, specialty chemicals, and food processing, the relentless pursuit of advanced materials and sophisticated product formulations consistently demands powders with exceptional characteristics. Achieving uniform particle size distribution, consistent morphology, and uncompromising purity from liquid or slurry feedstocks is critical for product performance, process efficiency, and market competitiveness. Traditional drying methods often struggle to meet these exacting standards, especially for fine or sensitive materials. Spray drying stands out as a sophisticated, direct conversion process that excels in producing high-performance powders, addressing these precise needs. This article explores how leading Industrial Spray Dryer technology, as exemplified by Sinothermo’s engineering expertise, delivers the uniformity e purity essential for today’s advanced industrial applications.

The Challenge: Demanding Requirements for Industrial Powders

Modern industrial applications require powders that are more than just dry solids. They must possess engineered properties to function optimally. Key challenges include:

- Precise Particle Size Distribution (PSD): Uniformity is paramount for consistent solubility, dispersion, flowability, and compressibility. Variations can lead to product defects, inconsistent performance, and processing issues.

- High Purity & Minimal Contamination: Especially critical in pharmaceuticals and food, absolute purity is non-negotiable to ensure safety, efficacy, and compliance with stringent regulatory standards. Even trace contaminants can compromise final product integrity.

- Controlled Morphology: The physical shape and structure of particles influence bulk density, flow, and processing behavior.

- Stability & Reactivity: Powders must remain stable under storage and exhibit predictable reactivity during downstream processing.

- Efficiency & Scalability: Manufacturers need reliable, scalable processes that can deliver consistent quality at production volumes.

Traditional drying techniques like tray drying or drum drying can be slow, energy-intensive, and prone to agglomeration or degradation, failing to meet the nuanced requirements for fine or specialty powders.

Spray Drying: Engineering Powders with Precision Control

Spray drying is a highly efficient method for converting liquid feedstocks (solutions, suspensions, emulsions, or slurries) directly into dry, solid powder particles in a single step. The process involves atomizing the liquid into fine droplets within a hot drying medium (typically air or inert gas). These droplets undergo rapid heat and mass transfer, leading to instantaneous drying and the formation of discrete powder particles. This controlled evaporation allows for:

- Direct Liquid-to-Powder Conversion: Eliminates intermediate steps, enhancing efficiency.

- Rapid Drying Process: Minimizes thermal degradation and preserves sensitive compounds.

- Particle Formation Control: The outcome is a fine, often spherical, powder.

Achieving Uncompromising Powder Uniformity

O uniformity of spray-dried powders is a direct result of controlling the droplet and drying environment:

- Optimized Atomization: At the heart of fine powder production is effective slurry atomization. Whether through high-pressure nozzles or rotary atomizers, the goal is to generate a fine, homogenous spray of droplets with a narrow size range. This consistency in droplet size directly translates to consistent drying times and, consequently, uniform particle size in the final powder.

- Precise Process Parameter Management: Critical factors such as inlet and outlet air temperatures, airflow rate, and feed rate must be meticulously controlled. These parameters dictate the evaporation rate and residence time, directly influencing particle characteristics and preventing undesirable agglomeration or over-drying.

- Resulting Benefits: Powders with tightly controlled particle size distribution exhibit superior flowability, reduced dusting, improved compressibility (vital for tableting in pharma), and predictable dissolution rates in food ingredient drying and chemical applications. This controlled particle morphology ensures excellent performance in downstream processes and final product consistency.

Ensuring High Purity & Superior Quality

For applications where high purity powder is paramount, industrial spray dryer technology offers inherent advantages and can be further enhanced for maximum assurance:

- Contamination-Free Environment: For highly sensitive materials like Active Pharmaceutical Ingredients (APIs) or certain food ingredients, enclosed spray drying systems can be operated with inert gases (e.g., nitrogen) rather than air. This closed-loop system not only prevents oxidation but also minimizes the risk of airborne contamination, safeguarding product integrity.

- Material Selection: High-quality industrial spray dryers, like those engineered by Sinothermo, are constructed from carefully selected materials (often stainless steel grades) that are inert and resist corrosion, preventing metallic contamination of the product.

- Gentle Drying: The very rapid nature of the spray drying process means that heat exposure for individual particles is brief. This makes it ideal for heat-sensitive compounds that would degrade or lose efficacy under slower, more prolonged drying methods. This capability is crucial for preserving the delicate structure of enzymes, proteins, and complex chemical intermediates.

Key Industrial Applications of Precision Spray Drying

Sinothermo’s industrial spray dryer solutions cater to stringent requirements across multiple sectors:

- Chemical Powder Manufacturing:

- Specialty Chemicals: Catalyst powders, pigments, advanced ceramic materials, and polymer additives benefit from uniform particle size for consistent reactivity and dispersion properties.

- Fine Chemical Intermediates & APIs: Producing highly pure powder for pharmaceutical synthesis where precise particle morphology and residual solvent control are essential.

- Food Ingredient Drying:

- Emulsifiers & Stabilizers: Creating powders with specific surface properties and uniform particle size for optimal dispersion in food systems.

- Flavorings & Colorants: Encapsulating sensitive active compounds to protect them and ensure controlled release.

- Nutritional Powders: Infant formula, protein powders, and functional ingredients benefit from excellent solubility, dispersibility, and shelf-life stability derived from precise fine powder production.

- Advanced Materials: Producing homogenous powders for batteries, electronics, and other high-tech applications requiring extremely controlled physical properties.

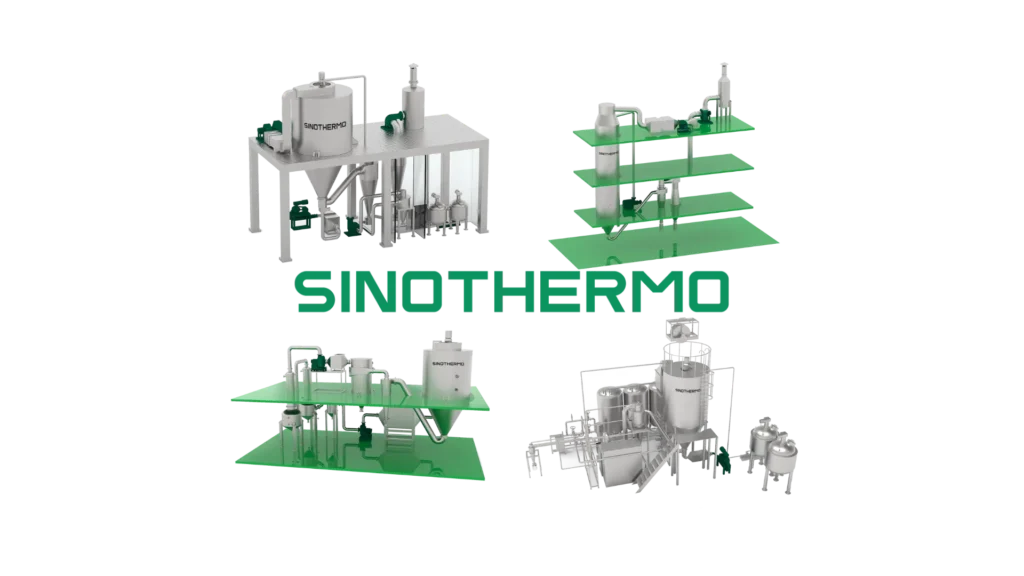

Sinothermo: Your Partner for Advanced Powder Processing

At Sinothermo, we understand that standard solutions rarely suffice for specialized industrial powder needs. Our commitment to engineering excellence means we offer:

- Customized Spray Drying Solutions: We design and manufacture industrial spray dryers tailored to your specific feed characteristics, desired particle properties, capacity requirements, and stringent purity standards.

- Expert Engineering & R&D: Our team possesses deep expertise in fluid dynamics, heat transfer, and particle engineering, ensuring optimal process design and slurry atomization for superior fine powder production.

- Robust & Reliable Equipment: Built for demanding industrial environments, Sinothermo spray dryers are designed for longevity, efficiency, and minimal downtime.

- Pilot Testing & Scale-Up Support: We can assist with pilot trials to validate your process and ensure seamless scale-up from laboratory to full production.

- Focus on Quality & Purity: Our designs prioritize contamination control and efficient drying, whether for general industrial use or highly sensitive pharmaceutical and food-grade applications.

Success Story Spotlight (Conceptual)

A leading global producer of specialized food emulsifiers faced challenges ensuring consistent emulsifying power and shelf-life stability due to variations in their drying process. By implementing a Sinothermo custom-engineered spray dryer, they achieved a remarkable reduction in particle size variation, leading to a 15% improvement in product dispersion uniformity and a significant extension of product shelf-life. This enhanced consistency directly translated to better performance in their customers’ final food products and reduced customer complaints by 20%.

Choosing the Right Industrial Spray Dryer for Your Needs

Selecting the most appropriate industrial spray dryer is a critical decision. Consider:

- The physical and chemical properties of your feedstock (viscosity, solids content, heat sensitivity).

- Your target particle size distribution, morphology, and bulk density.

- Necessário high purity powder levels and any specific regulatory compliance (e.g., GMP for pharma/food).

- Production capacity and desired process efficiency in terms of fine powder production.

- The potential for solvent recovery if using organic solvents in chemical powder manufacturing.

Partnering with an experienced equipment manufacturer like Sinothermo ensures that these factors are thoroughly evaluated, leading to an optimized solution that delivers superior powder quality and process economics.

Elevate Your Product Quality. Achieve Unrivaled Powder Performance.

Ready to transform your liquid or slurry feedstocks into high-performance powders with exceptional uniformity and purity? Contact Sinothermo today to discuss your specific requirements. Our experts are here to help you select or engineer the ideal industrial spray drying solution for your demanding applications.

Apaixonado por melhorar as experiências dos clientes e simplificar as operações, Mark concentra-se na construção de relações fortes, na promoção da inovação e na liderança de equipas para alcançar um serviço e uma eficiência excepcionais.

Correio eletrónico: mark.gu@sinothermo.com

Telefone: +86 18021972660