Executive Summary

Drying heat-sensitive, high-fat food products like coconut powder requires precise control over temperature and residence time to preserve solubility and preventing caking. This article details a specific engineering solution by Sinothermo utilizing the Vibrating Fluid Bed Dryer designed to reduce moisture content from 37% to under 2% while maintaining strict hygiene standards.

The Challenge: Drying High-Moisture Food Powders

In this specific project, the requirement was to process 1,100 kg/h of wet coconut powder.

- Initial Moisture: 30-40% (Targeting 37%)

- Target Moisture: 1.5-2%

- Material Characteristics: Fragile granules, heat-sensitive, slight stickiness due to fat content.

- Hygiene Standard: Zero cross-contamination permitted (Food Grade).

A standard single-pass dryer often fails to reach such low moisture levels without overheating the product. Therefore, Sinothermo engineered a continuous drying process.

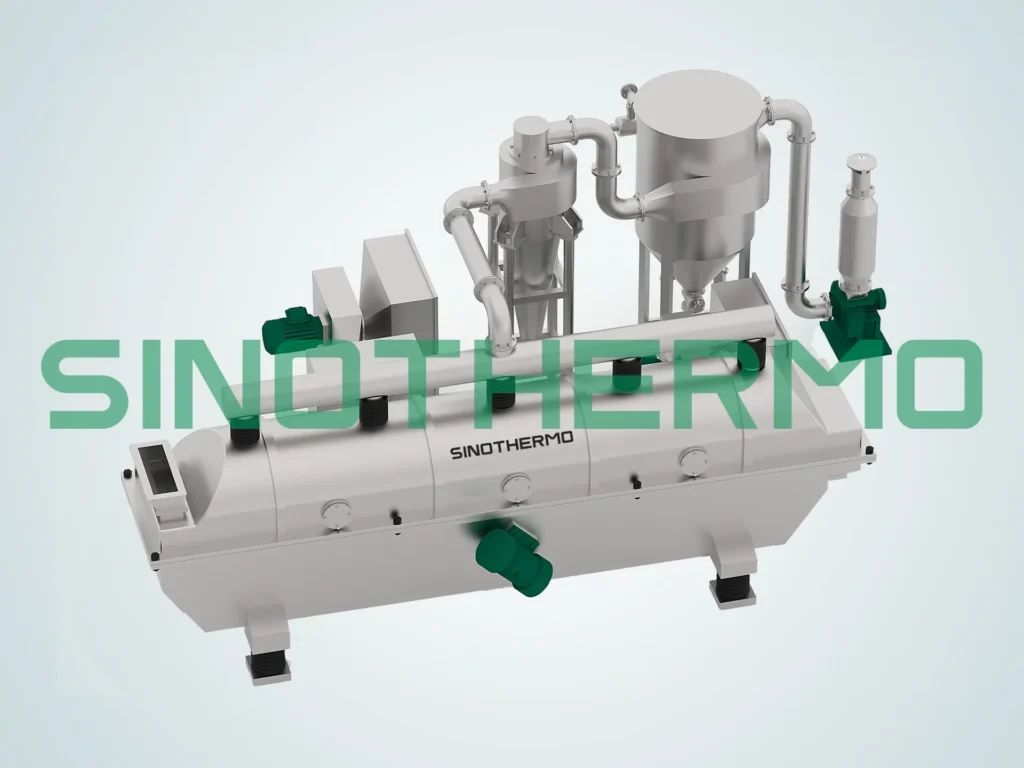

The Solution: Vibrating Fluid Bed Drying System

Sinothermo’s design utilizes the Vibrating Fluid Bed Dryer. The system combines mechanical vibration with hot air fluidization, ensuring efficient heat transfer and preventing the formation of “dead corners” or channeling.

Stage 1: Rapid Surface Moisture Removal

- Equipment: Vibrating Fluid Bed Dryer.

- Process: Wet material enters the first bed. Hot air at 130°C fluidizes the powder.

- Outcome: The bulk of the water is evaporated here. The moisture content drops from ~37% to 10-12%.

- Heat Recovery: Exhaust air is processed through a Pulse Bag Dust Collector to recover fine powder, minimizing yield loss.

Stage 2: Deep Drying and Cooling

- Equipment: Vibrating Fluid Bed Dryer (Integrated Drying & Cooling Sections).

- Drying Section: The semi-dried powder enters the second stage. Hot air further reduces internal bound moisture to the final target of 1.5-2%.

- Cooling Section: A dedicated section introduces natural ambient air (filtered) to cool the product to ≤35°C before discharge. This prevents the fat in the coconut powder from melting or clumping during packaging.

- Energy Efficiency: Tail gas from the second stage is routed to the heat exchanger of the first stage for secondary utilization, significantly reducing steam consumption.

Why Choose Sinothermo?

- Fluidization Stability: The vibration motor ensures smooth material flow even for irregular particle sizes, preventing material agglomeration.

- Adjustable Parameters: The material layer thickness, moving speed, and vibration amplitude are infinitely adjustable, allowing operators to fine-tune the residence time for different product batches.

- Sanitary Design: The system operates under micro-negative pressure in a fully enclosed structure. This ensures zero dust leakage and prevents external air from contaminating the food product. All contact parts are manufactured from high-grade SUS304 Stainless Steel.

- Advanced Control: The system is integrated with a Siemens PLC + DCS Control System with a 10-inch touch screen, providing automated temperature regulation, over-temperature alarms, and motor overload protection.

결론

For food and chemical manufacturers dealing with difficult-to-dry powders, the Vibrating Fluid Bed Drying System offers the optimal balance of efficiency and gentle handling. This coconut powder project demonstrates our ability to achieve precise moisture targets (<2%) while recovering waste heat and ensuring product quality.

Ready to optimize your drying process? 연락처 Sinothermo today for a customized drying solution tailored to your material characteristics.

고객 경험 향상과 운영 간소화에 열정을 쏟고 있는 마크는 강력한 관계 구축, 혁신 촉진, 팀을 이끌어 뛰어난 서비스와 효율성을 달성하는 데 주력합니다.

이메일: mark.gu@sinothermo.com

전화: +86 18021972660