Sinothermo is committed to ensuring our clients achieve optimal performance from our advanced industrial machinery. Following the successful delivery of the LPG-5 Lab Spray Dryer to AGT in South Korea for their LFP (Lithium Iron Phosphate) production, our dedicated engineering team visited AGT’s facility to provide comprehensive on-site training for equipment operation. This collaborative session focused on empowering AGT’s personnel with the knowledge and best practices for maximizing the efficiency and product quality of their new spray dryer.

The Need for Precision in LFP Material Drying

The production of LFP, a critical component in modern battery technology, demands highly precise and controlled processes. Key challenges in drying LFP materials include:

- Consistent Particle Morphology: Achieving uniform particle size and shape is crucial for efficient electrochemical performance and battery density.

- Moisture Control: Strict limits on residual moisture are essential to prevent degradation and ensure the stability of the LFP cathode material.

- Material Handling of Fine Powders: LFP powders can be difficult to handle, requiring specialized techniques to prevent loss and ensure consistent feed.

- Process Optimization: Fine-tuning operating parameters like inlet/outlet temperatures, airflow, and feed rate is critical for optimal results without compromising material integrity.

AGT selected Sinothermo’s LPG-5 Lab Spray Dryer for its tailored capabilities to address these specific needs in LFP manufacturing.

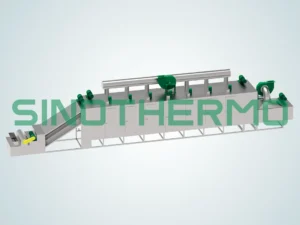

The LPG-5 Lab Spray Dryer: Engineered for LFP Applications

The LPG-5 Centrifugal Spray Dryer, as configured for AGT, is designed with the unique demands of LFP material processing in mind. Key specifications include:

- Input Material: Specifically configured for the mixture of H2O, FePO4, and Li2CO3.

- Target Particle Size: Capable of achieving D50 between 5-25 µm and D90 less than 100 µm, ensuring fine granularity.

- Processing Capacity: Designed for a significant evaporation rate of 5 kg/h, suitable for laboratory or pilot-scale LFP production needs.

- Operational Parameters:

- Inlet Air Temperature: Adjustable from 200 to 250°C

- Outlet Air Temperature: Adjustable from 100 to 120°C

- Moisture Content Output: Highly controlled within 0.4-0.5%

- Construction: Critical components in contact with the material are made of SUS304 stainless steel, ensuring purity and corrosion resistance essential for battery materials.

- Control System: Features a PLC control system with a Siemens interface, allowing for precise automation and monitoring of critical parameters.

These specifications, combined with the inherent advantages of centrifugal spray drying, make the LPG-5 an ideal solution for producing high-quality LFP powders.

Comprehensive On-Site Training for AGT

Understanding that successful operation begins with skilled personnel, Sinothermo dispatched our experienced engineers to AGT’s facility in South Korea. The objective was to provide hands-on guidance on the operation of the LPG-5 Lab Spray Dryer, supplementing the initial delivery. The training covered:

- System Overview & Familiarization: A detailed walkthrough of each component, including the feeding system, heating system, drying chamber, atomization, and material collection.

- Pre-Operational Checks: Ensuring all systems were ready and safe for operation.

- Parameter Setting & Optimization: Guidance on configuring inlet air temperature, outlet air temperature, feed rate, and atomizer speed based on specific LFP material characteristics. This included understanding how to adjust these parameters to achieve the desired particle size and moisture content.

- Start-up and Shut-down Procedures: Safe and efficient methods for initiating and concluding the drying process.

- Material Handling Best Practices: Techniques for introducing and collecting LFP powder to minimize loss and contamination.

- Routine Maintenance: Essential checks and cleaning procedures to ensure the longevity and consistent performance of the equipment.

- Troubleshooting Basic Issues: Equipping AGT’s team to identify and address minor operational challenges.

- Safety Protocols: Reinforcing all safety guidelines relevant to operating the spray dryer.

Our engineers worked collaboratively with AGT’s team, answering questions and demonstrating techniques to ensure a thorough understanding of the equipment’s operational nuances for LFP production.

The Sinothermo Commitment: Partnership Beyond Delivery

This on-site training underscores Sinothermo’s dedication to being more than just an equipment supplier. We strive to be a technological partner, investing in our clients’ success by:

- Providing Expert Guidance: Leveraging our deep understanding of drying technologies and specific material applications.

- Ensuring Operational Excellence: Empowering our clients to operate our equipment safely, efficiently, and to its full potential.

- Supporting Innovation: Facilitating advancements in industries like battery manufacturing through reliable and precisely engineered solutions.

Looking Forward

Sinothermo is confident that the LPG-5 Lab Spray Dryer, coupled with the knowledge gained from our on-site training, will significantly contribute to AGT’s LFP production capabilities. We look forward to a continued successful partnership as AGT leverages this technology to produce high-performance battery materials.

Call to Action

Are you operating in the battery materials sector or another demanding industry and seeking a reliable spray dryer solution for precise particle control and moisture management? Sinothermo offers a range of advanced spray dryers, including the LPG-5, tailored for critical applications.

Contact Sinothermo today to:

- Discuss your specific material drying needs for LFP or other advanced materials.

- Learn more about the LPG-5 Centrifugal Spray Dryer and its capabilities.

- Inquire about our on-site training and technical support services.

- Request a personalized quote for laboratory or industrial-scale drying solutions.

Visit us at https://www.sinothermo.com or email us at info@sinothermo.com. Let’s engineer your success together.

Ghairah untuk meningkatkan pengalaman pelanggan dan memperkemas operasi, Mark menumpukan pada membina hubungan yang kukuh, memupuk inovasi dan memimpin pasukan untuk mencapai perkhidmatan dan kecekapan yang luar biasa.

e-mel: mark.gu@sinothermo.com

telefon: +86 18021972660