In the grand landscape of modern industrial manufacturing, the drying process is far more than a simple step for moisture removal; it is a core operation that dictates the physical characteristics, chemical stability, and commercial value of the final product. Within the framework of “Process Engineering Infrastructure,” industrial belt dryers have evolved from traditional thermal equipment into highly integrated, modular, and intelligent systems. This evolution reflects a global manufacturing pursuit of peak production efficiency, energy utilization, and product consistency across sectors such as food processing, fine chemicals, and advanced material synthesis.

Deep Analysis of Thermodynamic Principles and Drying Kinetics

The core operational logic of an industrial belt dryer is built upon the principles of controlled convective heat transfer. Unlike conduction drying, which relies on direct contact, convection drying utilizes circulating hot air as both the energy carrier and the moisture transport medium. At the thermodynamic level, the drying process is a complex dynamic equilibrium of heat and mass exchange, with efficiency governed by air temperature, humidity, flow velocity, and the physical structure of the material bed.

Three Stages of Moisture Migration and the Energy Threshold

The removal of internal moisture typically follows three critical thermodynamic stages: the preheating stage, the constant-rate drying stage, and the falling-rate drying stage. During preheating, the material absorbs heat, and internal moisture begins migrating to the surface. In the subsequent constant-rate stage, the material surface maintains the wet-bulb temperature, and the evaporation rate is dictated by external mass transfer conditions. During the most challenging falling-rate stage, moisture migration is governed by internal capillary forces and diffusion resistance; at this point, precisely adjusting belt speed and airflow direction is crucial to prevent surface overheating and internal cracking.

| Drying Stage | Heat Transfer Mechanism | Key Control Variables | Impact on Quality |

|---|---|---|---|

| Preheating | Convective Sensible Heat | Inlet Temperature | Prevents surface hardening |

| Constant-Rate | Latent Heat of Vaporization | Air Velocity/Humidity | Determines initial output |

| Falling-Rate | Internal Diffusion | Residence Time/Belt Speed | Ensures final moisture content |

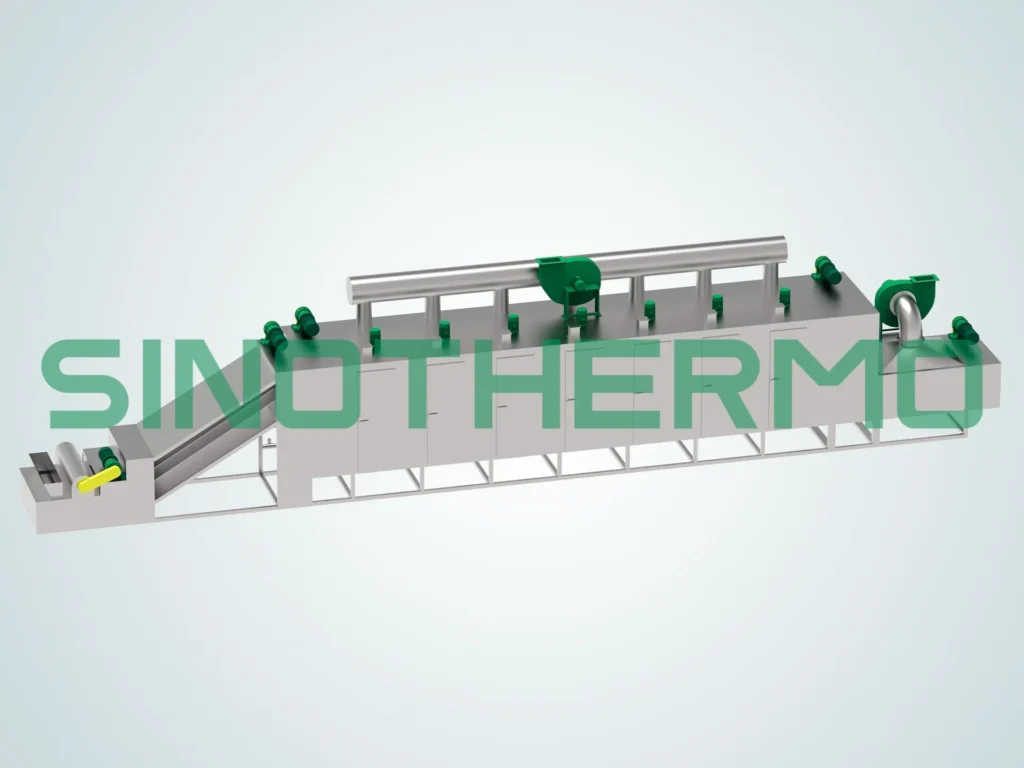

Modular Structural Engineering and Sanitary Applications

To meet the flexibility requirements of global supply chains, modern belt dryers adopt a modular design. This architecture not only optimizes long-distance logistics but also significantly shortens the onsite assembly and commissioning cycle. Each functional module can be precision-preassembled and leak-tested in a factory environment, ensuring that thermal efficiency targets are met upon final delivery.

Advanced Insulation and Fully Welded Sanitary Construction

At the infrastructure level, environmental control within the dryer is paramount. Utilizing high-grade stainless steel for a fully welded inner lining effectively prevents water vapor from seeping into the insulation layer, thereby avoiding microbial growth and latent heat loss. Insulation materials such as aluminum silicate wool, known for extremely low thermal conductivity, ensure that external wall temperatures remain within a safe range, complying with industrial ergonomics and energy-saving standards.

| Structural Component | Recommended Material | Technical Advantage |

|---|---|---|

| Outer Enclosure | SUS304 Stainless Steel | Structural strength and weather resistance |

| Inner Lining | SUS316 Stainless Steel | Superior corrosion resistance and hygiene |

| Thermal Insulation | Aluminum Silicate Wool | High-temperature stability |

| Sealing System | Foamed Silicone | Airtightness and durability |

Chain-Drive Systems: Reliability in High-Load Environments

In continuous production, the stability of the conveying system is directly linked to the operational efficiency of the entire line. Compared to traditional friction drives, chain-driven mesh belt systems demonstrate incomparable advantages when handling high-load, large-capacity materials. Through the mechanical positive engagement of sprockets and chains, the system eliminates belt slippage and deviation, ensuring absolute precision in conveying speed.

Engineering Logic of Positive Engagement

The chain-drive system connects power chains at both ends through transverse support rods, with the mesh belt fixed securely to these rods. This structure transfers the traction force from the delicate mesh belt to robust engineering chains. This design not only significantly extends the service life of the mesh belt but also allows the system to operate at extreme temperatures, which is vital for processes involving high-temperature heat treatment. Furthermore, the positive constraint of the chain ensures synchronized movement across large drying chambers, preventing mechanical damage caused by uneven tension.

Airflow Organization and Thermal Efficiency Optimization

In Industrial Belt Dryer Systems, the circulation path of hot air determines the uniformity of moisture removal.10 Modern designs utilize lateral circulation and independent unit air distribution technologies. This approach forces hot air to penetrate vertically through the material layer, achieving maximized heat utilization across the depth of the material bed.

Unitized Temperature Control

Each set of circulating fans and heaters forms an independent thermodynamic unit. By setting differentiated wind speeds and temperature gradients across various drying sections, the system can simulate complex process curves. For instance, at the material inlet, high air volume is used to prevent “case hardening,” while at the discharge end, low-temperature air is employed to ensure final product consistency. The lateral circulation structure also positions heaters at the side of the mesh belt, preventing material debris from falling onto heating elements, which eliminates fire hazards and maintenance difficulties.

Energy Recovery and Industrial Heat Pump Integration

In the context of global decarbonization, the energy efficiency ratio of industrial drying systems has become a key metric for technological leadership. Convection drying inherently involves significant exhaust emissions, which contain abundant sensible and latent heat.

Secondary Tail Gas Utilization and Closed Thermal Cycles

To reduce the unit consumption of energy, advanced systems introduce secondary tail gas utilization. This system reintroduces exhaust gas—which remains at a high temperature and low humidity after the final stages—into the initial preheating zone. This cascading energy utilization can reduce overall energy consumption by approximately15%-25%. Furthermore, the intervention of industrial heat pumps is transforming traditional heat source structures by recovering low-grade waste heat and upgrading it to process levels, maintaining highly efficient operation with minimal energy input.

| Energy-Saving Tech | Principle | Expected Efficiency Gain |

|---|---|---|

| Waste Heat Recovery | Exchanger-based heat extraction | 15%- |

| Industrial Heat Pumps | Reverse Carnot Cycle energy upgrade | 30%- |

| VFD Adaptive Control | Real-time load speed adjustment | 20%- |

| Regenerative Braking | Deceleration energy feedback | 5%- |

Intelligent Monitoring and IoT-Driven Maintenance

The wave of Industry 4.0 has pushed drying equipment from being “mechanical devices” to “data nodes”. By integrating high-precision sensor networks, modern belt dryers achieve full-dimensional monitoring of the production process.

Sensor Matrices and AI Decision-Making

Real-time sensors provide feedback on residual moisture, allowing the control system to automatically correct belt speed or inlet air temperature, ensuring batch consistency. Regarding mechanical health, vibration sensors on bearings and motors capture subtle spectral anomalies. AI algorithms can provide warnings weeks before a potential failure, achieving “zero unplanned downtime”. IoT technology also supports remote diagnosis, allowing engineers to provide instant technical support through cloud platforms regardless of the equipment’s geographic location.

The value of industrial drying equipment is defined by its Total Cost of Ownership (TCO) over a 15–20 year life cycle. A scientific maintenance protocol is the cornerstone of ensuring sustained efficiency.

- Adhesion and Cleaning: For sticky materials, systems are equipped with automatic rotating brushes or air knives at the discharge end to remove residues in real-time.

- Automatic Tracking: Pneumatic cylinders monitor belt edge positions, automatically micro-adjusting drive angles to eliminate the risk of belt tearing caused by manual error.

- Sanitary Access: By incorporating “quick-opening” structures and internal radius transitions, maintenance teams can perform internal inspections in minutes, a critical factor for high-productivity facilities.

Conclusion: A Vision for Future Process Infrastructure

Industrial belt dryer has transcended the stage of simple thermal conversion, entering a new era of process innovation and digital intelligence. As a core component of process engineering infrastructure, their modular flexibility and broad adaptability to diverse solids make them a powerful tool for global manufacturing enterprises. With the continued integration of green energy and AI, these systems will provide the technical foundation for the sustained prosperity of global industries.

Ivey cemerlang dalam menyampaikan arahan syarikat dengan berkesan melalui strategi pemasaran dan perhubungan awam yang berkesan, mempamerkan kepakarannya dalam bidang tersebut.

e-mel: ivey.tang@sinothermo.com

telefon: +86 19105155639