Einführung

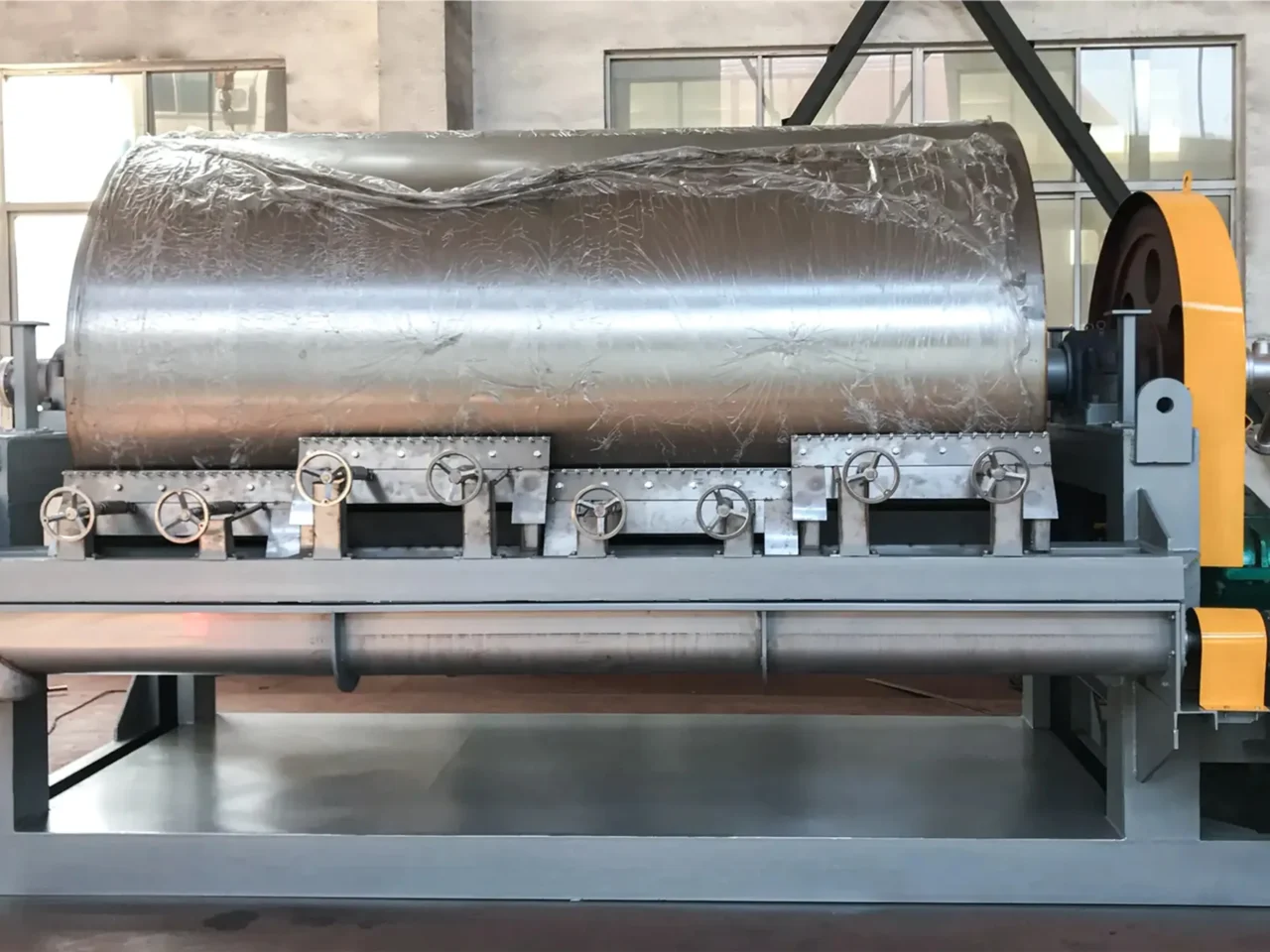

The HG1618-Drum Scraper Dryer by Sinothermo is an advanced industrial equipment for drying liquid sugar beet molasses and fish feed design. This rotary drum dryer leverages advanced internal heating conduction technology to ensure precise temperature control, consistent performance, and high-quality output. Whether you are in the food processing or livestock feed industry, Sinothermo’s drum scraper dryer provides an efficient and reliable method for drying heat-sensitive materials.

In this article, we will explore how the HG1618-Drum Scraper Dryer can meet your production needs while maintaining operational efficiency, safety, and compliance with industry standards. By understanding its design principles, technical configurations, and real-world applications, you’ll gain insights into why this equipment stands out among competitors.

Overview

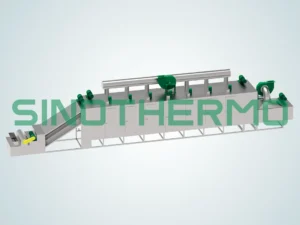

Die HG1618-Drum Scraper Dryer is engineered for continuous operation and capable of handling viscous liquids like liquid sugar beet molasses and slurry materials such as fish feed. The core mechanism involves applying heat through a rotating metallic drum that comes into contact with the liquid material via conduction, resulting in uniform drying without damaging sensitive components of the raw material.

Key Features:

- Internal Heating Conduction Type Rotary Drum Drying

- Suitable for Liquid Sugar Beet Molasses and Fish Feed

- Robust Construction using High-Quality Materials

- Precise Temperature Control via Thermostatic System

- Low Maintenance Requirements

- High Efficiency & Reduced Energy Consumption

How It Works

The HG1618 operates on the principle of heat transfer through conduction, where the heated metal drum rotates continuously, causing the incoming liquid material (such as sugar beet molasses) to form a thin film on the surface of the drum. As the drum spins, the material absorbs heat from the drum wall, which is maintained at a constant high temperature due to circulating thermal oil.

Process Flow:

- Material Feeding: The liquid material is fed into the system through a distribution device.

- Film Formation: Upon entering, the material flows over the rotating drum surface, forming a thin, even layer.

- Heat Transfer: Heat is transferred via conduction between the drum surface and the material, leading to evaporation of moisture.

- Drying & Scraping: Once dry, the solidified product is scraped off the surface of the drum by precision-cut scrapers.

- Discharge & Collection: The dried product then moves through additional machinery for collection, packaging, or further processing.

- Exhaust Gas Management: Airborne particles and volatile substances are filtered and collected before release into the atmosphere.

This continuous cycle ensures optimal efficiency and minimal material waste, making the HG1618 an ideal choice for industries requiring consistent batch production.

Advantages Over Competitors

The HG1618 boasts a meticulously crafted structure designed for maximum efficiency and longevity. Here are some key advantages:

- Feinmechanik: Each component undergoes rigorous testing and calibration to ensure top-tier performance.

- High-Temperature Resistance: The use of specialized alloys allows the drum to withstand extreme temperatures without deformation.

- Energieeffizienz: With optimized heat transfer mechanisms, energy consumption is significantly reduced compared to traditional drying methods.

- User-Friendly Controls: Advanced control systems enable easy setup and operation, minimizing operator training requirements.

- Geringer Wartungsaufwand: Fewer moving parts reduce wear and tear, extending service life and decreasing downtime.

Application Scenarios

- Lebensmittelverarbeitung: Ideal for drying sugar beet molasses used in various confectionery products and beverages.

- Pharmazeutika: Can be used for drying certain types of paste-like pharmaceutical intermediates.

- Feed Manufacturing: Perfect for producing high-quality fish feed that require precise moisture content levels.

- Chemikalien: Suitable for drying chemical slurries and suspensions.

- Biotechnologie: Used in bioprocesses where controlled drying of biological materials is required.

Why Choose Sinothermo?

At Sinothermo, our commitment to innovation, customer satisfaction, and sustainability drives everything we do. Our team of experts combines decades of experience in industrial drying solutions with cutting-edge technology to deliver machines that perform flawlessly under any condition.

With the HG1618-Drum Scraper Dryer, you get:

- A partner dedicated to meeting your unique production challenges

- Comprehensive support, including installation, training, and after-sales services

- Continuous improvements based on feedback from satisfied customers worldwide

Abschluss

With its ability to handle complex materials like liquid sugar beet molasses and fish feed, the HG1618-Drum Scraper Dryer is an indispensable tool for businesses seeking a blend of efficiency and reliability.

Whether you’re looking to upgrade existing operations or expand your production capacity, Sinothermo’s HG1618-Drum Scraper Dryer offers unparalleled performance and value. Don’t miss out on the opportunity to transform your drying processes with one of the industry’s most innovative machines.

Er konzentriert sich auf den Aufbau starker Beziehungen, die Förderung von Innovationen und die Führung von Teams, um außergewöhnlichen Service und Effizienz zu erreichen.

E-Mail: mark.gu@sinothermo.com

Telefon: +86 18021972660