The Growing Demand for Premium Rice Protein and Flour

The global demand for plant-based proteins is experiencing significant growth, driven by increasing consumer awareness of health, sustainability, and ethical considerations. Rice protein, in particular, stands out due to its hypoallergenic nature, making it an ideal choice for individuals with sensitivities to common allergens like soy and dairy. High-quality rice protein and flour are essential ingredients in a wide array of applications, including nutritional supplements, protein bars, baked goods, and plant-based dairy alternatives.

However, achieving the desired quality and functionality in rice protein and flour is not without its challenges. The processing steps, particularly drying, can significantly impact the final product’s characteristics. Inefficient or improperly controlled drying can lead to:

- Nutrient Degradation: Excessive heat can degrade essential amino acids and vitamins, reducing the nutritional value of the final product.

- Compromised Protein Functionality: Protein denaturation or alteration can negatively affect its solubility, emulsifying properties, and foaming capabilities – critical attributes for ingredient performance.

- Texture and Palatability Issues: Inconsistent moisture content or over-drying can result in undesirable textures, impacting the consumer experience.

- Reduced Yield: Product loss due to inefficient moisture removal or particle attrition during drying can impact profitability.

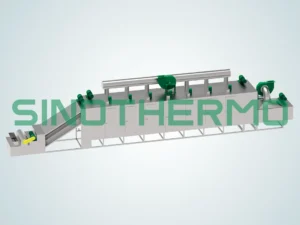

Sinothermo’s Essiccatore flash: Precision Drying for Superior Rice Protein

To meet the stringent demands of the market and overcome these processing hurdles, manufacturers require drying equipment that offers unparalleled control and efficiency. Sinothermo’s Essiccatore flash is engineered to deliver exactly that, making it the ideal choice for processing rice protein and flour.

Our Flash Dryer utilizes a specialized design where the wet material is rapidly dispersed and dried in a hot air stream. This method offers several key advantages crucial for optimizing rice protein quality:

- Precise Temperature Control: The Flash Dryer allows for accurate regulation of the drying air temperature. This is critical for preventing heat-induced degradation of heat-sensitive amino acids and preserving the protein’s native structure and functionality. Our systems ensure that temperatures are optimized for efficient moisture removal without causing thermochemical damage.

- Optimized Airflow Dynamics: The carefully engineered airflow within the dryer ensures rapid and uniform contact between the hot air and the material particles. This consistent exposure leads to even drying, preventing localized overheating or under-drying. The result is a homogeneous product with consistent moisture content.

- Minimized Residence Time: The inherent nature of flash drying means materials spend a very short time in the drying chamber. This brief but intense exposure further minimizes the risk of thermal degradation, safeguarding the nutritional profile and functional properties of the rice protein.

- Enhanced Protein Functionality: By preserving the protein’s structure, our Flash Dryer helps maintain vital functional properties such as solubility and emulsification. This translates to superior performance in end-product formulations, allowing food and supplement manufacturers to create products with improved texture, stability, and nutritional impact.

- Maximized Yield and Efficiency: The efficient moisture removal and gentle handling of particles in the Flash Dryer minimize product attrition and loss. This translates to higher overall yield and improved processing efficiency, directly impacting your bottom line.

Preserving Nutritional Integrity: The Sinothermo Advantage

One of the paramount concerns in processing rice protein is preventing the loss of valuable nutrients. The natural enzymes and heat sensitivity of certain amino acids mean that traditional drying methods can lead to significant degradation. Sinothermo’s Flash Dryer’s control protocols are specifically designed to mitigate these risks.

By carefully balancing drying temperature, air velocity, and residence time, our equipment ensures that moisture is removed efficiently while the delicate protein structures remain largely intact. This approach is vital for producing rice protein ingredients that meet high nutritional standards and deliver on their promised health benefits.

Achieving Optimal Texture and Consistency

Beyond nutritional value, the texture and consistency of rice flour and protein powder are critical for consumer acceptance and product performance. Sinothermo’s Essiccatore flash contributes to superior texture by:

- Uniform Moisture Removal: Consistent dryness across all particles prevents clumping and ensures a free-flowing powder.

- Controlled Particle Size: The drying process, often integrated with milling capabilities, can also help achieve desired particle size distributions, influencing mouthfeel and dispersibility.

- Preservation of Natural Characteristics: By avoiding drastic thermal changes, the dryer helps retain the inherent characteristics of the rice grain, contributing to a clean flavor profile.

Elevate Your Rice Protein Production with Sinothermo

The market for high-quality, plant-based protein ingredients is expanding rapidly. To capitalize on this trend, manufacturers need reliable, efficient, and technologically advanced processing equipment. Sinothermo’s Essiccatore flash offers a proven solution for producing premium rice protein and flour that meets the highest standards of quality, nutritional value, and functional performance.

Ready to unlock the full potential of your rice protein products?

Contact us today for a personalized consultation and to request a quote on our advanced Flash Dryer solutions.

Appassionato del miglioramento dell'esperienza dei clienti e della semplificazione delle operazioni, Mark si concentra sulla creazione di relazioni forti, sulla promozione dell'innovazione e sulla guida dei team per ottenere un servizio e un'efficienza eccezionali.

E-mail: mark.gu@sinothermo.com

Telefono: +86 18021972660