Protecting Active Ingredients

The pharmaceutical industry demands precision and control at every stage of production. Drying, a crucial step in many manufacturing processes, presents a significant challenge when dealing with heat-sensitive active pharmaceutical ingredients (APIs). Conventional drying methods often expose these delicate substances to high temperatures, leading to degradation, loss of activity, and ultimately, compromised product quality. This article delves into the challenges of drying heat-sensitive pharmaceuticals and explores the superior effectiveness of vacuum drying techniques in preserving the integrity and efficacy of these valuable compounds.

Challenges of Drying APIs

Traditional drying methods, like tray drying or spray drying, rely on elevated temperatures to evaporate moisture. While effective for many materials, this heat exposure can be detrimental to APIs. The common challenges include:

- Degradation: High temperatures can break down the molecular structure of APIs, rendering them ineffective or even creating undesirable byproducts.

- Loss of Activity: The therapeutic activity of some pharmaceuticals is directly related to their structural integrity. Heat-induced changes can diminish or eliminate this activity.

- Discoloration: Many sensitive compounds darken or change color under heat, affecting the visual appeal and perceived quality of the final product.

- Reduced Solubility: Drying at high temperatures can alter the API’s physical properties, making it less soluble and impacting its bioavailability.

- Caking and Hardening: Uneven drying can lead to caking and hardening of the powder, creating problems in downstream processing and dosage form preparation.

Vacuum Drying: A Gentle Solution

Vacuum drying offers a compelling solution to these challenges. By reducing the ambient pressure, the boiling point of water is significantly lowered. This allows for evaporation to occur at much lower temperatures, minimizing the risk of heat damage. SINOTHERMO offers a range of advanced vacuum drying equipment specifically designed for the pharmaceutical industry.

Benefits of Vacuum Drying

- Low-Temperature Operation: Evaporates moisture at significantly lower temperatures, preventing API degradation.

- Reduced Drying Time: The vacuum environment accelerates the evaporation process, leading to faster drying cycles.

- Uniform Drying: Ensures consistent moisture content throughout the product batch, preventing caking and improving flowability.

- Solvent Recovery: Vacuum drying systems can be equipped with solvent recovery systems, crucial for reclaiming valuable solvents and minimizing environmental impact.

- Improved Product Quality: Minimizes degradation, preserves activity, and maintains the desired physical properties of the API.

SINOTHERMO’s Vacuum Drying Solutions

SINOTHERMO offers a comprehensive range of vacuum drying equipment tailored to the specific needs of pharmaceutical manufacturers. Our solutions include:

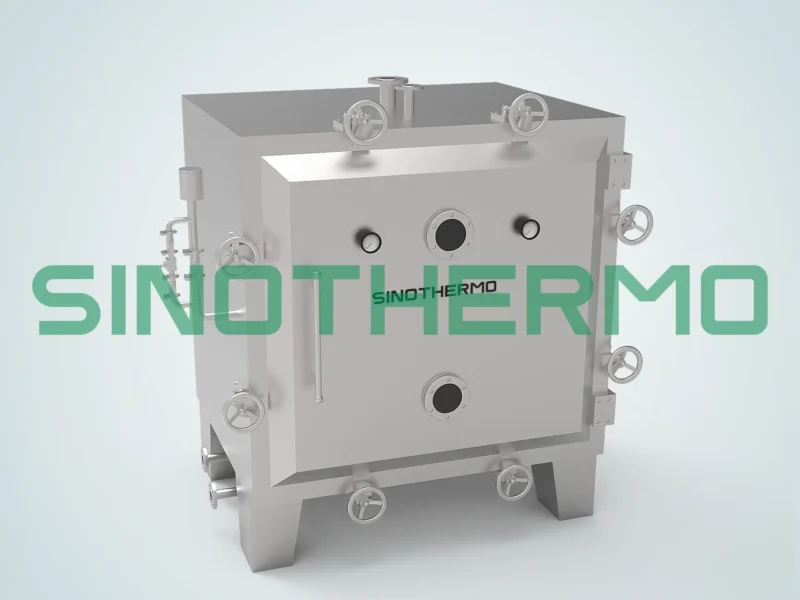

- Pengering Kabinet Vakum Statik: Efficient tray dryer with large-area heating tubes. Preserves material properties making it ideal for heat-sensitive, flammable, or explosive materials.

- Pengering Plat Menegak Vakum: Continuous conduction with efficient disc heating. Ideal for flammable, explosive, and heat-sensitive materials.

- Pengering Cakera Mendatar Vakum: Offers enhanced heating. Optimized for heat-sensitive, organic solvent-based, and flammable materials.

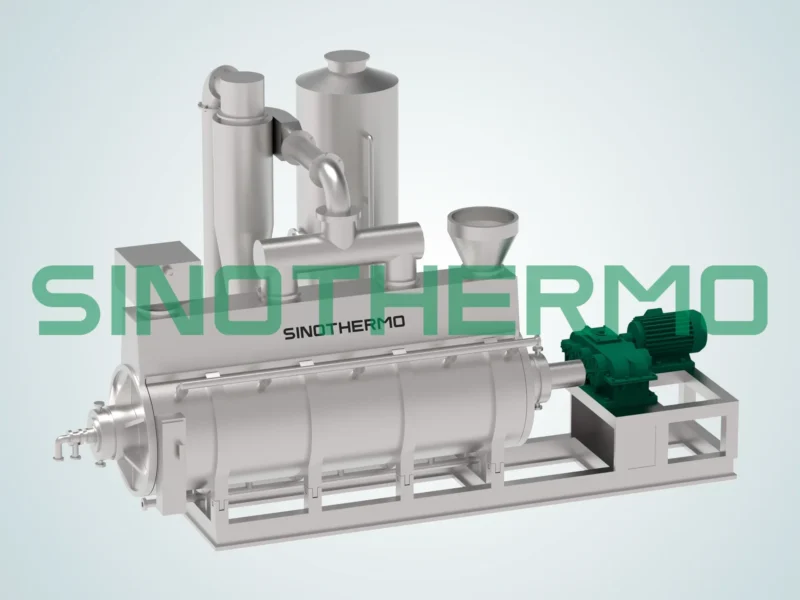

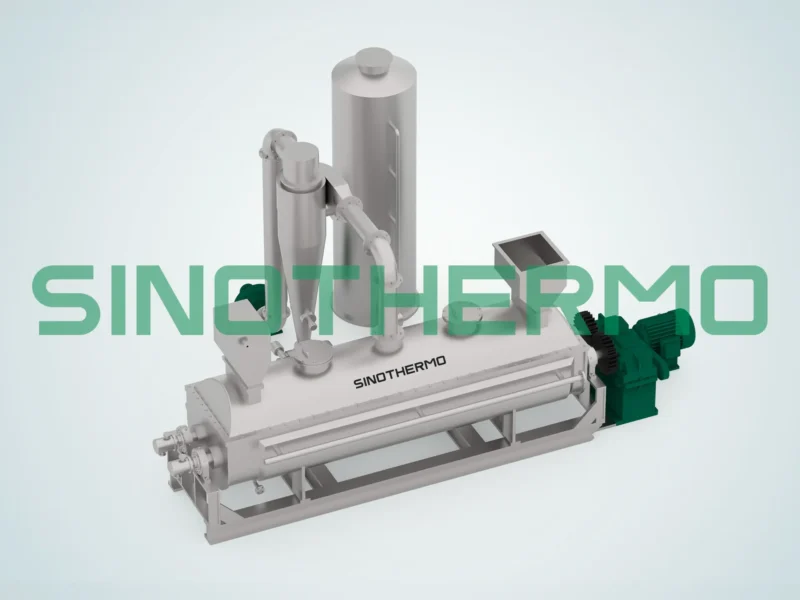

- Pengering Dayung Vakum: Features hollow paddle agitators for efficient heating and material movement. Ideal for heat-sensitive, flammable, and organic solvent-based materials.

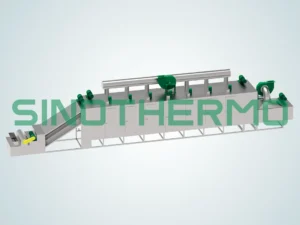

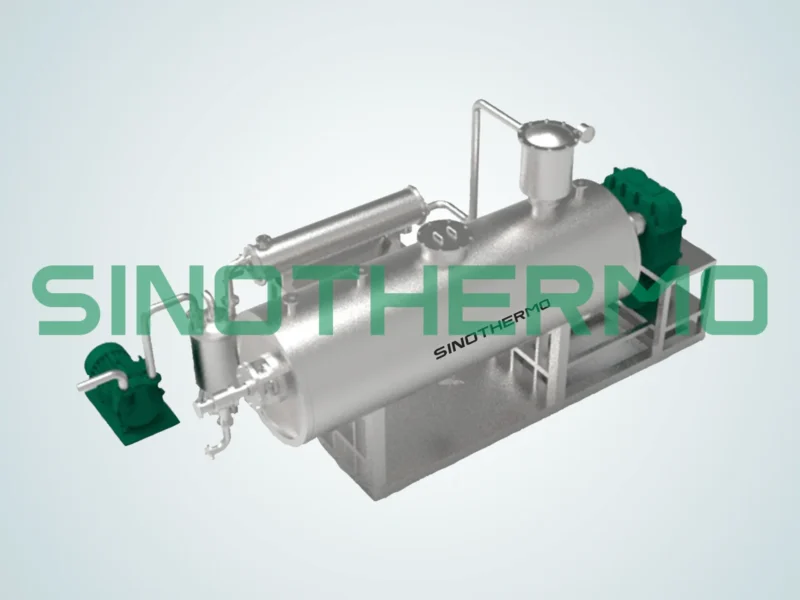

- Pengering Rake Vakum: Possesses a large heating surface area. Perfect for heat-sensitive materials and organic solvents.

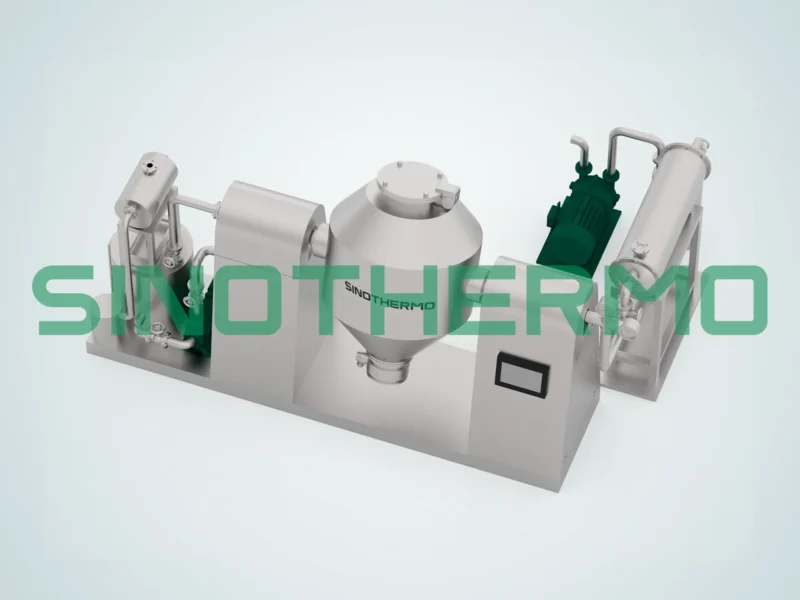

- Pengering Vakum Rotary Kon Berkembar: Offers effective blending with a smooth interior. Suitable for heat-sensitive materials.

- Pengering Vakum Kon Ribbon: Offers efficient heating, mixing, and smooth discharge. Designed for heat-sensitive and explosive materials.

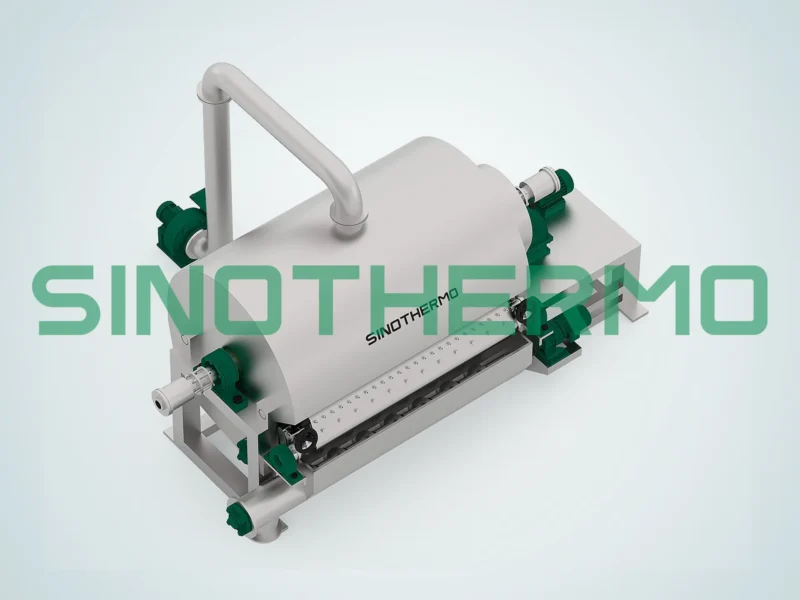

- Pengering Pengikis Drum Vakum: When using drying for paste materials the rotating drum sticks the material, onto it creating a thin layer. Heat moves from the inside, to the outside of the drum effectively removing moisture.

Partnering for Optimal Drying

Choosing the right drying technology is crucial for ensuring the quality, efficacy, and safety of heat-sensitive pharmaceutical products. SINOTHERMO’s vacuum drying solutions provide a reliable and efficient way to overcome the challenges of drying temperature-sensitive APIs. By partnering with SINOTHERMO, pharmaceutical manufacturers can optimize their drying processes, minimize product degradation, and achieve superior product quality.

Ready to optimize your pharmaceutical drying process? Contact SINOTHERMO today for a consultation and custom drying solution tailored to your specific needs.

Ivey cemerlang dalam menyampaikan arahan syarikat dengan berkesan melalui strategi pemasaran dan perhubungan awam yang berkesan, mempamerkan kepakarannya dalam bidang tersebut.

e-mel: ivey.tang@sinothermo.com

telefon: +86 19105155639