The Starch Drying industry demands highly efficient and controlled drying solutions to achieve optimal product quality, yield, and functionality. Sinothermo offers a range of advanced drying technologies, including Flash Dryers and Spin Flash Dryers, each with distinct advantages. This guide explores the differences between these units, empowering starch manufacturers to select the ideal equipment for their specific needs, from production volume and starch type to desired product characteristics, ultimately driving profitability and market competitiveness.

The Critical Role of Drying in Starch Production

Starch, a vital component in food, pharmaceutical, textile, and paper industries, undergoes a crucial drying phase after its extraction and purification. This step is paramount for several reasons:

- Moisture Reduction & Shelf-Life Extension: Removing excess water is essential to prevent microbial spoilage and extend the shelf life of starch products.

- Product Functionality: The drying process significantly influences starch’s physical properties, such as particle size, flowability, solubility, and gelatinization temperature, which are critical for its downstream applications.

- Yield Optimization: Efficient drying minimizes product loss and ensures maximum recovery of valuable starch solids.

- Energy Efficiency: Modern drying equipment must achieve these objectives while minimizing energy consumption, a key factor in operational costs.

However, starch is a sensitive material. Inappropriate drying conditions can lead to:

- Starch Degradation: Over-drying or excessively high temperatures can cause irreversible changes to starch granules, affecting their crystalline structure and functional performance.

- Clumping and Agglomeration: Poorly controlled airflow or insufficient particle dispersion can result in uneven drying, leading to sticky lumps that are difficult to process and affect product uniformity.

- Color Changes and Off-Flavors: Thermal stress can cause Maillard reactions or caramelization, resulting in undesirable browning and altered taste profiles.

- Reduced Flowability: Inconsistent moisture levels or particle morphology can lead to poor handling characteristics, impacting packaging, transportation, and further processing.

Understanding the Technologies: Flash Dryer vs Spin Flash Dryer

Sinothermo’s expertise lies in providing drying solutions that precisely address these challenges. Two of our leading technologies for starch processing are the Flash Dryer and the Spin Flash Dryer. While both leverage the principle of hot gas drying, their operational mechanics and suitability for different applications vary significantly.

1. The Essiccatore flash: Rapid Drying for Dispersible Materials

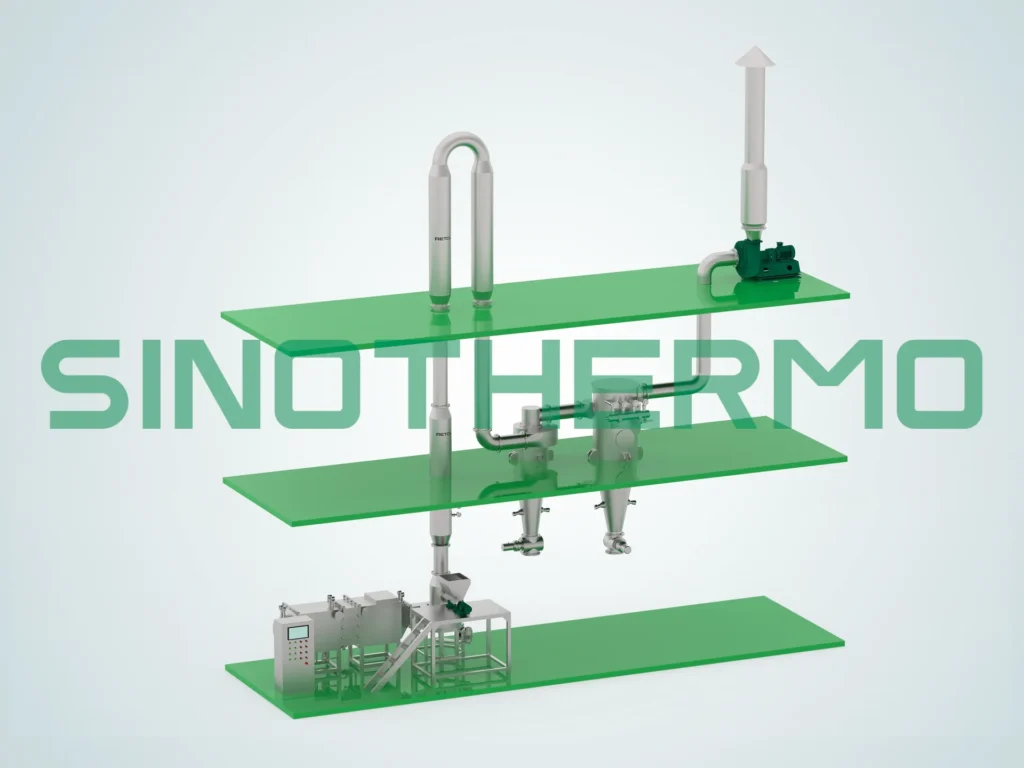

How it Works: The Flash Dryer, also known as a pneumatic dryer, is designed for drying finely divided or paste-like materials. In this system, wet material is atomized or disintegrated into fine particles within a hot air stream. The particles are then pneumatically conveyed through a drying duct, where rapid heat and mass transfer occur. The dried particles are separated from the air in a cyclone collector.

Ideal Applications for Starch Processing:

- Starch Pastes and Slurries: Highly effective for drying starch that has been processed into a paste or very fine slurry.

- Heat-Sensitive Starch Derivatives: Suitable for materials that require very short residence times and efficient drying to preserve delicate properties.

- Smaller Production Volumes: Can be an excellent choice for facilities with moderate throughput requirements.

Vantaggi principali:

- Extremely Short Drying Time: Materials are dried in seconds, minimizing the risk of thermal degradation.

- Uniform Drying: Efficient dispersion in the hot air stream promotes consistent moisture removal.

- Continuous Operation: Designed for high throughput and continuous processing.

- Compact Design: Generally requires less installation space compared to other dryer types.

Considerations:

- Requires the material to be in a suitable form (e.g., paste, slurry) or capable of being easily disintegrated.

- Particle size control might be a secondary factor, often requiring additional milling.

2. The Asciugatrice Flash a centrifuga: Integrated Drying and Agglomeration for Powders

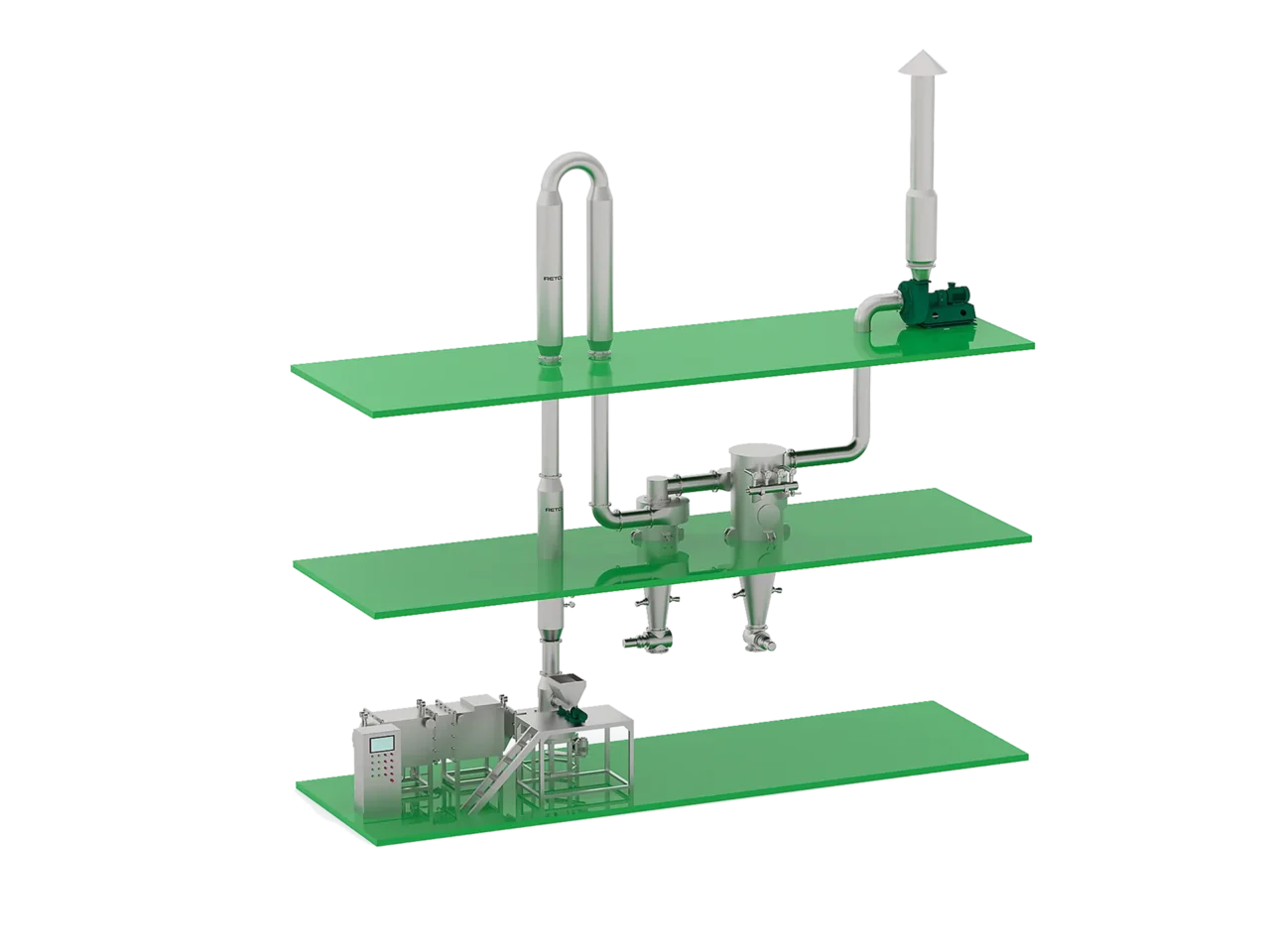

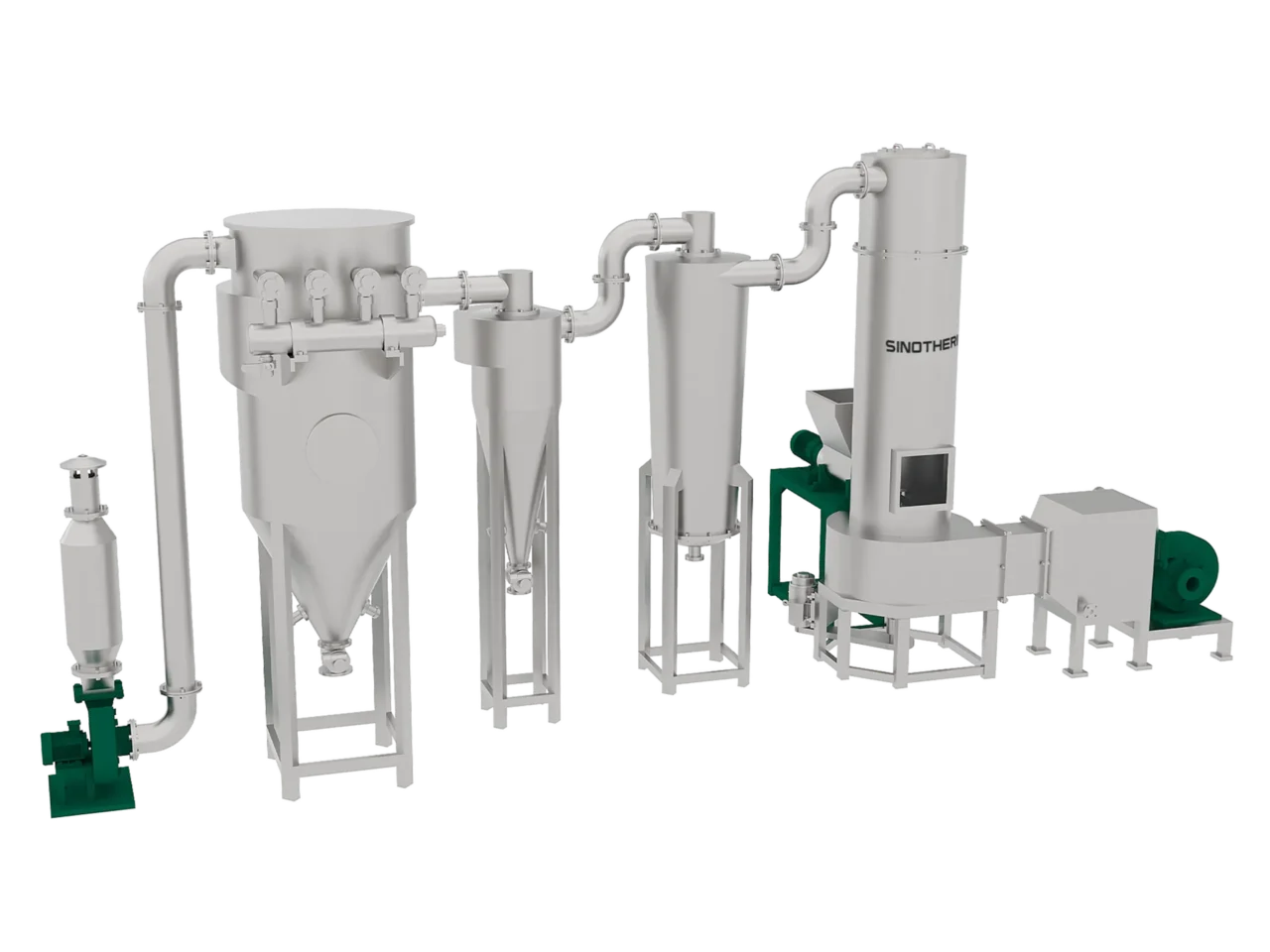

How it Works: The Spin Flash Dryer combines the principles of a Flash Dryer with a specialized disintegrator rotor at the bottom of the drying chamber. Wet material is fed into the hot air stream and simultaneously broken down by the high-speed rotating blades of the disintegrator. This action ensures excellent particle dispersion, while the integrated design facilitates the simultaneous drying and deagglomeration (or controlled agglomeration, depending on settings) of the material. Dried, free-flowing powder is then collected from subsequent cyclones.

Ideal Applications for Starch Processing:

- Wet Starch Cakes or Filter Flakes: Excellent for directly drying filter cakes from starch processing, eliminating the need for pre-milling in many cases.

- Producing Free-Flowing Starch Powders: The disintegration action is highly effective in creating uniformly sized, free-flowing starch granules.

- Larger Production Volumes: The robust design and efficient processing make it suitable for high-capacity industrial operations.

- Controlled Particle Morphology: Can achieve desired particle size distributions and flow characteristics.

Vantaggi principali:

- Highly Efficient for Cakes and Flakes: Can directly process materials that are not in a slurry form.

- Integrated Disintegration & Drying: Simplifies the process flow and reduces equipment footprint.

- Excellent Product Flowability: Produces consistently free-flowing starch powders.

- Precise Control over Particle Size: The rotor speed can be adjusted to tailor the final particle characteristics.

- High Throughput Capacity: Designed for demanding industrial production rates.

Considerations:

- Requires a sufficiently powerful disintegrator, which may contribute to higher energy consumption depending on the material’s consistency.

- While drying is fast, the disintegration action can introduce slightly more thermal stress compared to a pure, pre-atomized Flash Dryer, though still minimal and controllable.

Sinothermo’s Expertise: Tailoring the Solution to Your Starch

Choosing between a Flash Dryer and a Spin Flash Dryer for your starch plant is a strategic decision that hinges on several key factors:

- Feed Material Characteristics: Is your input a pumpable slurry/paste, or a wet cake/flake?

- Production Capacity: What is your required daily or hourly output?

- Desired Product Properties: What are the critical specifications for your final starch product (e.g., particle size distribution, flowability, moisture content, color)?

- Integration with Upstream/Downstream Processes: How does the dryer fit into your existing production line?

At Sinothermo, we don’t just sell equipment; we provide comprehensive drying solutions. Our team of experienced engineers works closely with clients to:

- Analyze Feed Material: We assess the physical and chemical properties of your starch feedstock.

- Define Product Specifications: We help clarify the precise characteristics required for your end-use applications.

- Evaluate Production Needs: We understand your capacity requirements and operational constraints.

- Recommend the Optimal Technology: Based on this analysis, we recommend either our advanced Essiccatore flash or our integrated Asciugatrice Flash a centrifuga, or potentially a hybrid solution, ensuring it perfectly matches your process.

- Provide Customized Design & Support: We offer bespoke engineering, installation, commissioning, and ongoing technical support to ensure maximum efficiency and longevity of your drying system.

Elevate Your Starch Processing with Sinothermo

The competitive landscape of the starch industry demands efficiency, consistency, and superior product quality. By understanding the nuances between Flash Dryers and Spin Flash Dryers, and by partnering with an expert like Sinothermo, you can equip your plant with the optimal drying solution. Our commitment to innovation, quality, and customer success ensures that you achieve maximum value from your starch processing operations.

Ready to optimize your starch drying process and achieve unparalleled product quality?

Contact Sinothermo today for a personalized consultation and to discover how our advanced Flash Dryer and Spin Flash Dryer solutions can revolutionize your production. Request a no-obligation quote and let us help you unlock the full potential of your starch.

Ivey eccelle nel trasmettere efficacemente le direttive aziendali attraverso strategie di marketing e di pubbliche relazioni di grande impatto, mettendo in luce la sua esperienza nel settore.

E-mail: ivey.tang@sinothermo.com

Telefono: +86 19105155639