Industrial operations worldwide are grappling with the escalating challenge of managing liquid waste and sludge. High disposal costs, stringent environmental regulations, and the potential for resource recovery necessitate efficient waste reduction solutions. This article explores the critical role of slurry drying technologies in mitigating these challenges. It provides an in-depth guide to understanding different slurry types, their inherent drying difficulties, and critically evaluates Sinothermo’s advanced drying equipment – the CD Dryer, Vacuum Drum Scraper Dryer, Paddle Dryer, and Vacuum Rake Dryer. By detailing key selection factors, this guide aims to empower manufacturers to choose the optimal slurry drying solution for their specific needs, driving cost savings, environmental compliance, and operational efficiency.

Introduction: The Growing Burden of Industrial Slurry and the Promise of Slurry Drying

The modern industrial landscape is characterized by continuous innovation and production, but this progress also brings a significant byproduct: industrial waste liquid and sludge. Global statistics reveal an alarming increase in the volume and complexity of these waste streams. Manufacturers face mounting pressures from increasingly rigorous environmental regulations, soaring disposal costs, and the ever-present need to operate sustainably. Improper management not only incurs substantial financial penalties but also poses severe environmental risks.

Fortunately, a powerful solution exists: slurry drying. This transformative process effectively reduces the volume of waste liquids and sludges, making them significantly easier and more cost-effective to handle, transport, and dispose of. Beyond volume reduction, slurry drying can also unlock opportunities for resource recovery, turning potential liabilities into valuable assets.

At Sinothermo, we are at the forefront of developing and delivering advanced slurry drying technologies designed to meet the diverse needs of industries ranging from pharmaceuticals and food processing to chemicals and wastewater treatment. Our commitment lies in providing energy-efficient, reliable, and customized solutions that empower businesses to tackle their waste management challenges head-on. This article will guide you through the intricacies of selecting the most appropriate slurry drying technology for your unique operational requirements.

Learn more about our cutting-edge solutions at Sinothermo’s Slurry Drying Technologies.

Understanding Slurry and its Drying Challenges

Before delving into specific technologies, it’s crucial to understand what constitutes “slurry” and the inherent difficulties associated with its drying.

What is Slurry?

In industrial terms, slurry is a broad classification encompassing both liquid waste and sludge. It’s characterized by a high moisture content, often exceeding 80%, and can possess a wide range of physical and chemical properties. This can include fine solid particles suspended in a liquid medium, thick pastes, or even lumpy, semi-solid materials.

Types of Slurries Encountered in Industry:

- Industrial Wastewater Slurries: Byproducts from manufacturing processes, often containing chemicals, oils, suspended solids, and organic matter.

- Municipal Sludge: Dewatered biosolids from wastewater treatment plants, typically composed of organic solids, pathogens, and inorganic materials.

- Chemical Slurries: Suspensions generated during chemical manufacturing, which can be corrosive, abrasive, or contain valuable recoverable components.

- Food Processing Slurries: Residues from food production, such as fruit pulp, dairy byproducts, or brewing waste.

The Complexities of Slurry Drying:

Drying slurries is not a one-size-fits-all endeavor. Several inherent challenges must be effectively addressed by the chosen technology:

- High Moisture Content: The sheer volume of water requires efficient evaporative processes.

- Viscosity and Handling: Many slurries are highly viscous or sticky, presenting difficulties in material feeding and internal transport within the dryer.

- Potential for Scaling and Fouling: Sticky or adhesive materials can build up on dryer surfaces, reducing efficiency and requiring extensive cleaning.

- Energy Consumption: Evaporating large quantities of water is an energy-intensive process, making energy efficiency a paramount concern for cost-effectiveness.

- Volatile Compound Release: Some slurries may contain volatile organic compounds (VOCs) or other airborne contaminants that require careful containment and treatment.

Choosing the right slurry drying technology is therefore critical. It must be robust enough to handle these challenges, deliver consistent results, and operate economically while meeting stringent regulatory demands.

Sinothermo’s Advanced Slurry Drying Technologies

Sinothermo offers a comprehensive suite of drying solutions specifically engineered to address the diverse challenges of waste liquid drying Und sludge drying. We select the most appropriate technology based on the specific characteristics of your material, focusing on maximum efficiency and minimal energy consumption.

Waste Liquid Drying Solutions (Slurries above 80% Moisture)

For materials with very high moisture content, often described as flowable slurries or liquids, Sinothermo offers specialized solutions:

Die CD-Trockner is a highly efficient and energy-conscious solution designed for the effective drying of fluid-like materials. It utilizes a unique drying mechanism that optimizes heat transfer and mass exchange, ensuring rapid and uniform moisture reduction.

- Hauptvorteile:

- Compact Design: Requires a smaller footprint compared to conventional dryers.

- High Thermal Efficiency: Minimizes energy consumption through optimized heat recovery.

- Low Operating Costs: Reduced energy usage and simplified operation translate to significant cost savings.

- Effective with High Moisture Content: Specifically engineered to handle slurries with over 80% water.

- Versatile Application: Suitable for a wide range of flowable waste liquids and sludge.

- Ideal Applications: Waste liquids, chemical slurries, and fluid sludge with high water content.

- Primary Keywords: Slurry Drying, Waste Liquid Drying, CD Dryer, Waste Liquid

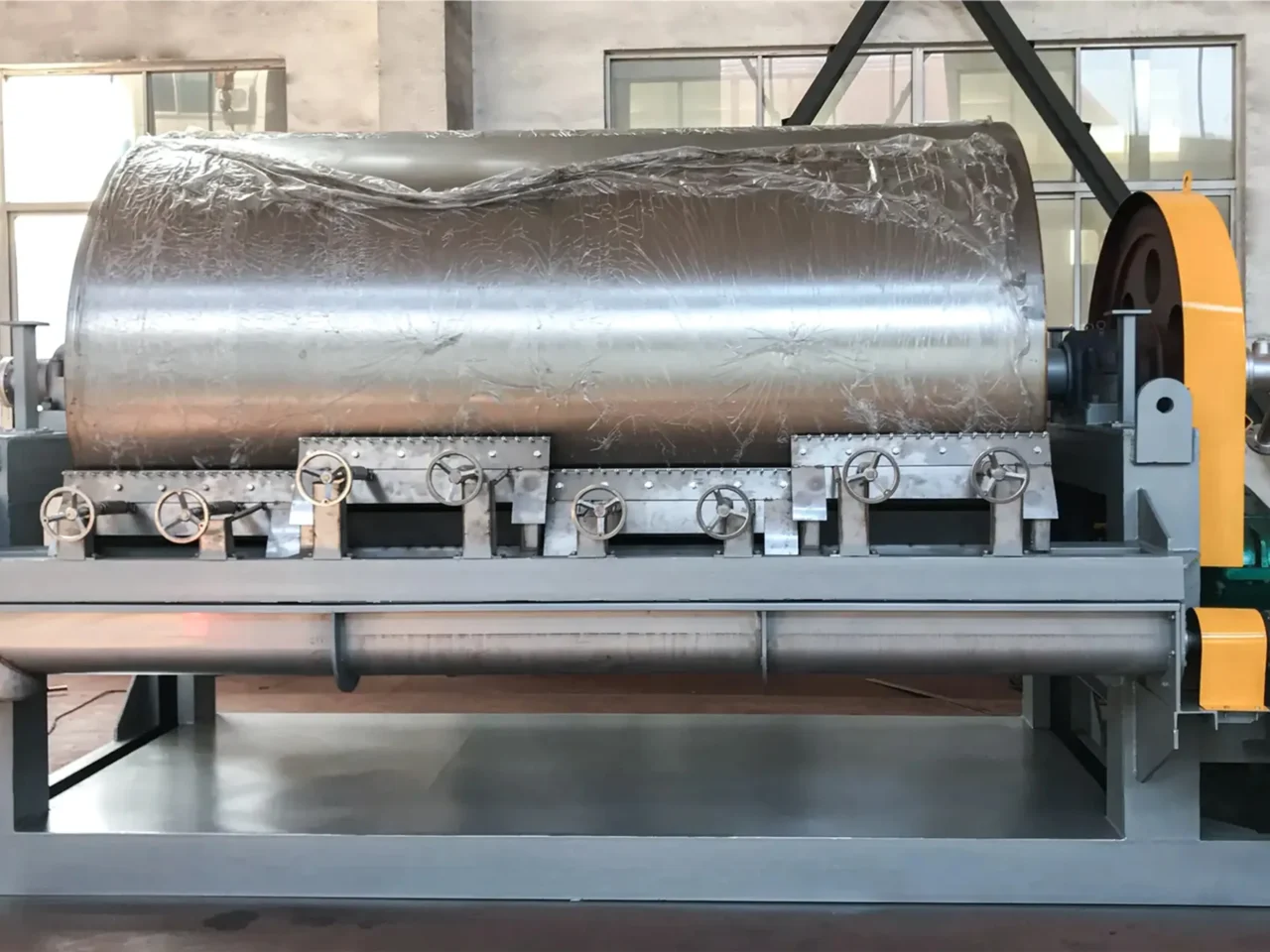

The Vacuum Drum Scraper Dryer is another robust option for waste liquid drying. Its design incorporates rotating rollers that apply a thin film of material, maximizing the surface area exposed to heated air, leading to rapid evaporation. An integrated scraper system continuously removes the dried material.

- Hauptvorteile:

- Continuous Operation: Designed for uninterrupted processing.

- Uniform Drying: Ensures consistent moisture reduction across the material.

- Efficient Moisture Removal: Handles high volumes of water effectively.

- Robust Construction: Built for demanding industrial environments.

- Ideal Applications: Similar to the CD Dryer, particularly effective for flowable slurries and waste liquids where consistent film formation is beneficial.

- Primary Keywords: Slurry Drying, Waste Liquid Drying, Vacuum Drum Scraper Dryer, Waste Liquid

Sludge Drying Solutions (Shaped Paste/Solid Sludge)

For materials that are more paste-like or already partially dewatered into a semi-solid or solid form, Sinothermo provides specialized sludge drying equipment:

Die Schaufeltrockner (also known as Blade Dryer) is a highly versatile and energy-efficient indirect heating dryer renowned for its ability to handle sludge, sludge soil, and other semi-solid waste materials. Its unique design features interlocking, heated paddles that agitate and convey the material, ensuring excellent heat transfer and effective drying.

- Hauptvorteile:

- High Thermal Efficiency: Indirect heating minimizes heat loss and optimizes energy usage.

- Effective Mixing and Agitation: The paddle design ensures thorough contact with heated surfaces, promoting uniform drying and preventing clumping.

- Suitable for a Wide Range of Materials: Effectively dries pastes, cakes, and granular solids.

- Customizable Design: Configurations can be tailored to specific material properties and throughput requirements.

- Low VOC Emissions: The enclosed system helps contain volatile compounds.

- Ideal Applications: Dewatered urban sludge, industrial sludge, chemical sludge, food processing waste, and other paste-like or solid waste materials.

- Primary Keywords: Schlammtrocknung, Sludge Soil Drying, Waste Sludge Drying, Paddle Blade Dryer, Blade Dryer, Dewatering

Die Vakuum-Rechentrockner is an exceptional choice for sludge drying, particularly when dealing with heat-sensitive materials or when lower operating temperatures are desired. Operating under vacuum, this dryer significantly reduces the boiling point of water, allowing for efficient drying at much lower temperatures. The internal raking mechanism ensures constant turning and mixing of the material, preventing caking and promoting even drying.

- Hauptvorteile:

- Vacuum Drying for Low-Temperature Processing: Ideal for materials that degrade at higher temperatures, preserving product quality.

- Effective for Heat-Sensitive Materials: Gentle drying process minimizes thermal damage.

- Efficient Mixing: The rake system ensures uniform exposure to heat and prevents agglomeration.

- Reduced Drying Time: The vacuum environment accelerates the evaporation process.

- Airtight Operation: Minimizes emissions and prevents contamination.

- Ideal Applications: Heat-sensitive sludge, pharmaceutical sludge, chemical sludge, food waste, and materials requiring gentle drying conditions.

- Primary Keywords: Schlammtrocknung, Sludge Soil Drying, Waste Sludge Drying, Vakuum-Rechentrockner, Heat-Sensitive Drying

Factors to Consider When Choosing a Slurry Drying Technology

Selecting the right slurry drying equipment is a critical decision that impacts operational efficiency, cost-effectiveness, and environmental compliance. Carefully consider the following factors:

- Material Characteristics: This is the most crucial factor. Analyze your slurry thoroughly:

- Moisture Content: Is it a liquid (<80% solids), a paste (e.g., 20-50% solids), or a cake/solid (e.g., >50% solids)? Technologies are optimized for different moisture ranges.

- Particle Size and Distribution: Affects flow properties and drying rates.

- Viscosity and Stickiness: Determines handling capabilities and resistance to fouling.

- Chemical Composition: Presence of corrosive, abrasive, or volatile substances influences material selection and safety protocols.

- Heat Sensitivity: Will the material degrade or change properties at elevated temperatures?

- Capacity Requirements: What is your desired daily or hourly throughput? The dryer must be sized appropriately to meet your production demands efficiently.

- Energy Efficiency: With rising energy costs, selecting a technology with high energy efficiency is paramount. Indirect drying methods and optimized heat recovery systems can lead to substantial long-term operational cost savings.

- Regulatory Compliance: Ensure the chosen drying technology and any associated emission control systems meet all local and national environmental regulations for waste disposal and air purity.

- Capital and Operating Costs: Consider both the initial investment in the equipment and the ongoing costs associated with energy consumption, maintenance, labor, and spare parts. A slightly higher upfront investment in an energy-efficient machine can yield significant returns over its lifespan.

Conclusion: Partner with Sinothermo for Superior Slurry Drying Solutions

Effectively managing industrial waste liquid and sludge is no longer just an operational necessity; it’s a strategic imperative for businesses aiming for sustainability, cost control, and regulatory compliance. Slurry drying offers a powerful pathway to achieve these goals by significantly reducing waste volume and potentially recovering valuable resources.

At Sinothermo, we are dedicated to providing innovative, energy-efficient, and customized slurry drying solutions. Our range of advanced equipment, including the high-performance CD-Trockner, the robust Vacuum Drum Scraper Dryer, the versatile Schaufeltrockner, and the gentle Vakuum-Rechentrockner, is engineered to meet the unique challenges of your specific applications.

Ready to transform your waste management and unlock new efficiencies?

We invite you to contact Sinothermo today for a personalized consultation. Our expert team will work closely with you to analyze your material and operational needs, recommending the most effective and cost-efficient slurry drying technology to optimize your processes.

Er konzentriert sich auf den Aufbau starker Beziehungen, die Förderung von Innovationen und die Führung von Teams, um außergewöhnlichen Service und Effizienz zu erreichen.

E-Mail: mark.gu@sinothermo.com

Telefon: +86 18021972660

-1024x929.webp)